BNSF and BRC: Coming together to forge a safer, more efficient future through new brake health technology

BNSF’s heritage spans 170-plus years, thanks in part to our visionary predecessors’ drive for innovation. We continue that tradition, especially when it comes to improving safety and service – and that’s why we‘re proud to work with the Brotherhood of Railway Carmen (BRC) to expand our Brake Health Effectiveness Program (BHE). Currently the program is a pilot on our Southern Transcon route, and we hope to expand it to our Powder River Division to service the coal market.

BHE relies on a relatively new thermal detector technology that measures the temperature of railcar wheels as a train passes by the detectors. The wayside detectors analyze the wheels’ temperature to ensure that braking systems are operating as they should. This allows us to more effectively monitor the brake health of our trains, enhancing safety and reducing service interruptions caused by braking issues.

First, the train runs past a detector without its brakes applied. This tests the temperature on all wheels, and if any are detected as running hot, it tells the carmen there could be an issue, like sticking brakes. If the wheels are detected running cold, the brakes are working as intended.

Then we check for the opposite issue: defective brakes. The train passes through a second detector with its brakes applied. If the train passes the detector and the wheels register as hot due to friction, it’s a good sign that the brakes on each car are working properly. The train then continues toward its destination, bypassing a manual inspection without stopping.

This process saves an average of 40 minutes of inspection time per train.

After four years of using BHE on intermodal and grain cars through a FRA test waiver on our Southern Transcon, BRC and BNSF are now partnering to request expansion of the test waiver to utilize BHE on coal cars operating in our Powder River Division.

“The BRC and BNSF are working together to support the expansion of a technology that has a positive impact on rail safety and train braking performance,” said Donald Grissom, General President, BRC.

Since implementing this new technology on select areas our Southern Transcon, there has been a 5% detection rate per cars inspected compared to a 0.04% detection rate through manual, visual inspections.

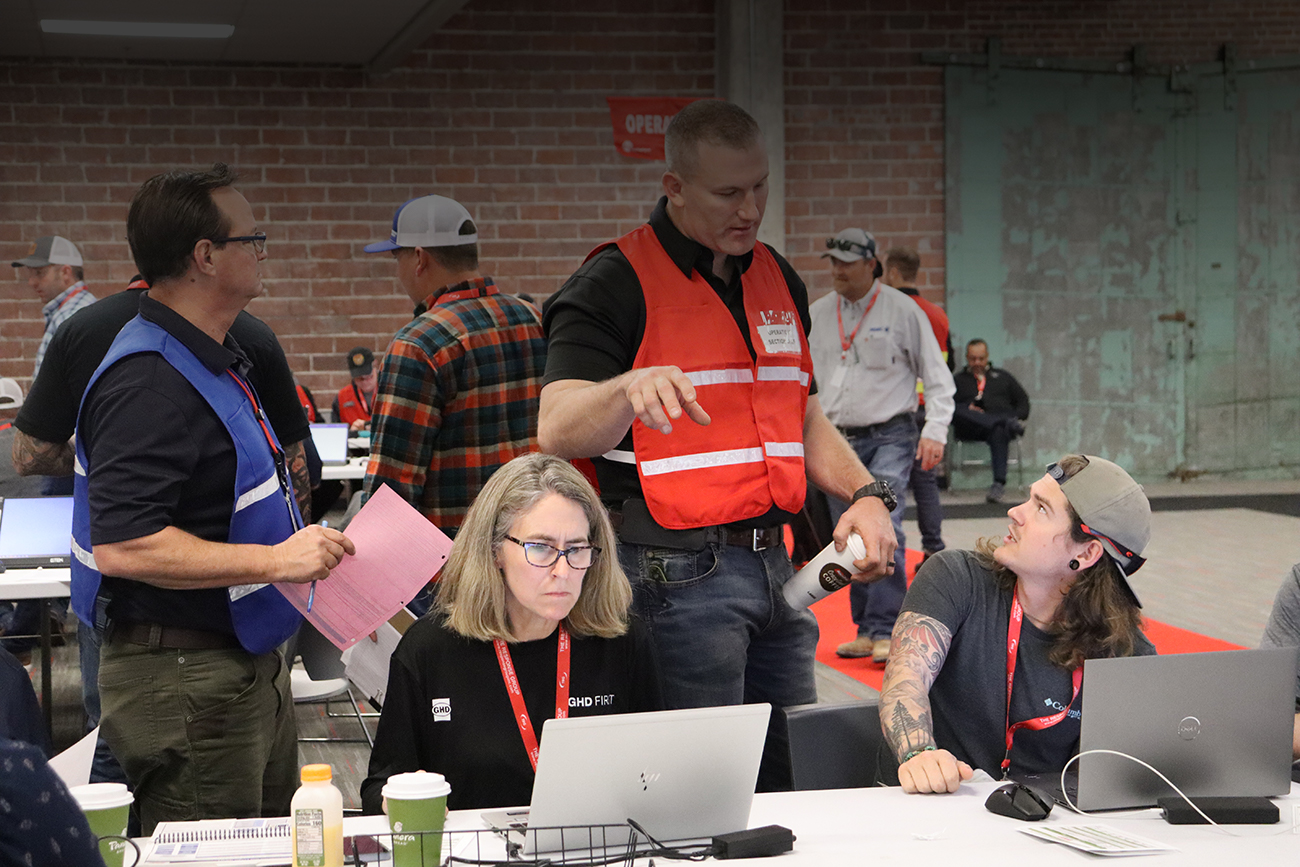

Using BHE to detect braking issues also means that our freight car inspectors are no longer problem finders, they have become problem solvers.

“We’re proud to partner with BRC to develop and implement technology that drives a safe and efficient rail network,” Keith Solomons, BNSF’s vice president, Mechanical, said. “Embracing technological developments like BHE not only creates a safer network, but ultimately allows us to grow the railroad together, which is in the best interest of all of us.”

At BNSF, we’re continuously looking for opportunities to innovate and to collaborate with all our employees. As we continue our work on BHE, we look toward to the future of rail service through the lens of safety and service efficiency for crews and customers alike.